Custom packaging is a great way to make your product stand out. It’s an extremely important part of the marketing process, and it can also help with customer service. If you’re looking for some advice on how to create custom packaging that increases sales, there are some processes that every company should know! We’ll dive into each of these processes so you can get more information. We’ll dive into each of these processes so you can learn what they’re all about.

How many processes for custom cylinder packaging?

Sourcing material

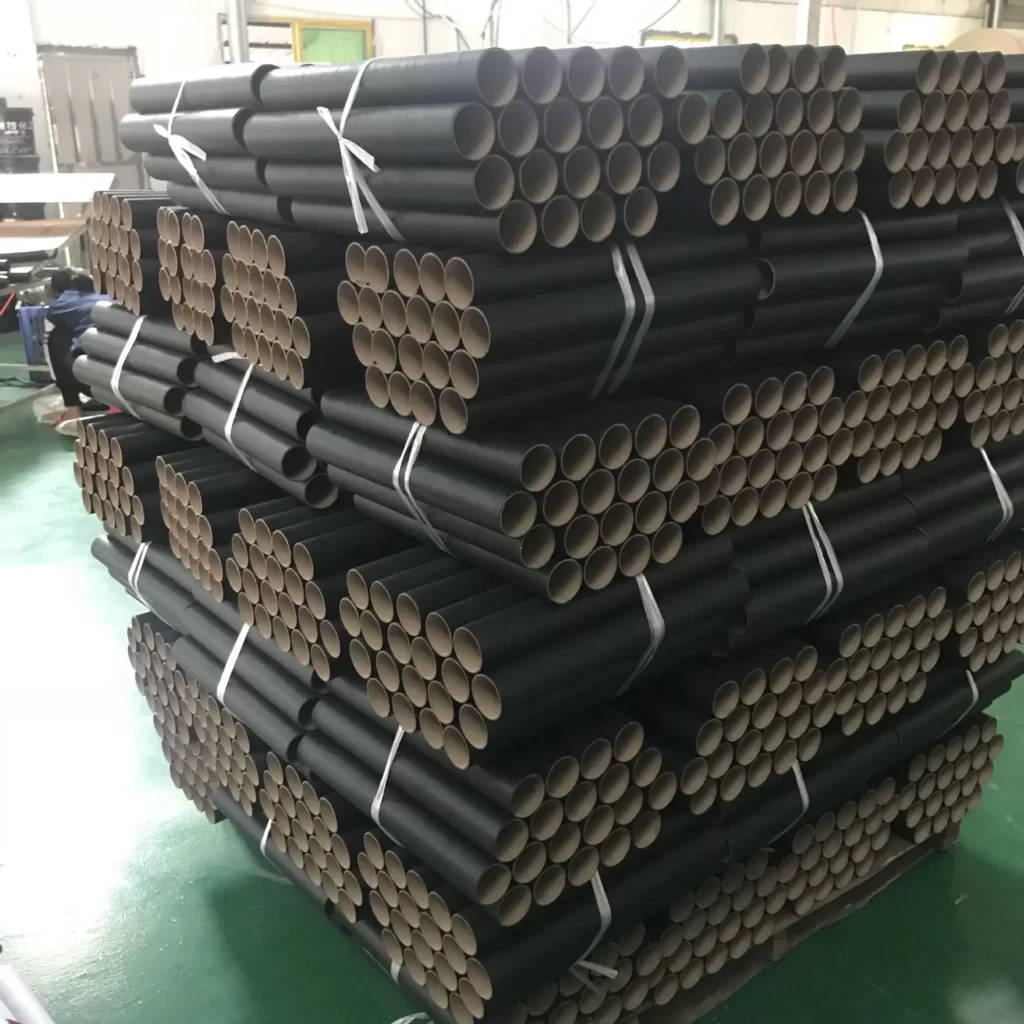

The perfect packaging tubes we will use come from a mill that ensures that all of its materials meet the strictest quality requirements. This means that these custom paper tubes are free of defects and look great when printed. It’s important to find a supplier you can trust, so you can be sure your packaging will look great!

Slitting:

Thick filling to be proportional, low moisture content, smooth appearance of the sand pipe paper as the main paper, the choice of impregnated paper as the surface paper, in accordance with the required specifications of high-end paper tube size, the custom tubes large volume and surface paper large volume placed in the slitting machine to develop slitting.

The raw material of paper in roll form is divided into narrow rolls of paper by a slitting machine in order to roll the tube.

Rolled

The rolled paper cut by slitting machine is loaded onto the paper tube frame, the glue tank is added with glue, and the equipment is run, the spiral roll of paper is formed, and the end has a cutting device to cut off the packaging tube.

Air Drying

Product packaging drying tries to keep upright to ensure straightness and roundness, the air with high humidity discharged from the humidity discharge window is best discharged to the outside of the workshop to avoid the hot air discharged from the shop to make up for the baking room again. Put the roughly cut paper tube section into the drying room until the moisture content of the paper tube is below 10%.

Rough cutting:

The product packaging is roughly cut into sections of a certain length after the resin-coated paper tube passes through the air dryer at a uniform speed.

Labeling (paper lamination):

Usually, the paper is first wound with several layers glued together to produce a “spiral wound paper tube”, and then laminated with a beautiful label, the paper tube is cut into the required size, and then each section of the paper tube will be mounted on the top/bottom of the seal, you can complete the entire processing of composite paper cans.

Drying:

Push the cart into the baking room, turn on the dryer and dry automatically (paper tube drying time 8 to 15 hours, temperature from 50, 55, 60, 65 degrees increments)

Precision cutting:

The extruded paper tube will be roughly cut according to the required size, and after cutting, the end face of the paper tube will be chamfered, coated and packaged, which will complete the production of the seamless high-grade paper tube.

Rolled edge 2-3 times:

During the paper can forming/sealing section, the upper rolled edge of the paper can is rolled outward to form a rolled edge opening, and the diaphragm can then be sealed directly with the coated can liner. The paper cans are spiral wound, with folded and lapped liner windings, and the lapped section is sealed with an ‘AnacondaSeam’ (anaconda bite) to ensure the tightness of the can.

Gluing:

How many layers of the main paper tape and the beveled disposal of the surface paper tape in order from top to bottom layer by layer staggered laminated rules into parallel into the paper tape glue machine, the main paper tape and the surface paper tape on the upper surface of the uniform coating of a layer of paper tube special glue.

Upper base plate:

The inner base plate has a gap with the same shape as the rotary folding connection plate, and the rotary folding connection plate is set in the gap.

Load the inner tube :

The inner box body also includes a first inner endplate, one side of which is folded and connected to the end face of the inner bottom plate, and the other side of which is folded and connected to the first inner cover plate.

Assembling :

lifting the inner bottom plate upward, lifting while making the inner bottom template and the rotating folding connecting plate turn toward the side close to the outer bottom, turning the rotating folding connecting plate 180° to stack with the outer bottom. when the inner bottom plate turns 90° to stack with the outer bottom.

fold the inner cover plate inward so that the inner cover plate is located above the inner bottom plate; then fold the first outer cover plate and the second outer cover plate inward to encapsulate the inner box body inside the outer box body.

Exterior cleaning:

After assembling, you need to wipe the exterior of the paper tube with a rag.

Quality inspection:

Whether the easy-open cover and the bottom cover are glued. Expand whether the aluminum platinum edge of the easy-open cover is broken.

Easy pull cover: hand dial the easy pull cover edge is loose, feel the edge is smooth, whether the aluminum platinum inner wall mouth deformation.

Inner wall: check whether the inner wall of the screw roll paper tube is smooth, whether there are scuff marks, whether there is dirt.

Easy to pull the cover and the paper tube sealing parts whether there is paper dust, there is no complete pressure seal.

Wrapping:

Wrap all the packages with PE film after the goods inspection.

Storage:

After the packing is completed, it can be directly into the warehouse or all according to the customer box specification method out of the warehouse.

Of course, customized packaging is not only a process, it also needs printing and coating. Let us see what it has the rest of the process as the following.

If you wanna a better product experience for the best digital printing quality, upload artwork in vector format. Adobe Illustrator AI or PDF formats work best. why need those files? because a clear artwork can be printed well when custom size packaging.

What is the difference between CMYK and Panton Color for custom paper tube packaging?

Cyan, Magenta, Yellow, and Key are the colors used in the printing process. The artwork is made up of spots of ink in these four colors by a printing press. when companies customize tubes, 95% of packaging usually uses eco-friendly printing.

A Pantone color code represents a specific shade. A Pantone color code can be used to describe colors.

Basically, it is the standard language for colors and we are likely to use it as a guide. An identification code number identifies each color in Pantone’s standard ‘Color Matching System.

Conclusion

Custom paper tubes create brand recognition and customer loyalty for start-ups. we are one of the top packagings manufacturers in China, if you want to purchase packaging with us, please contact us immediately, we will provide a cheap price for you.