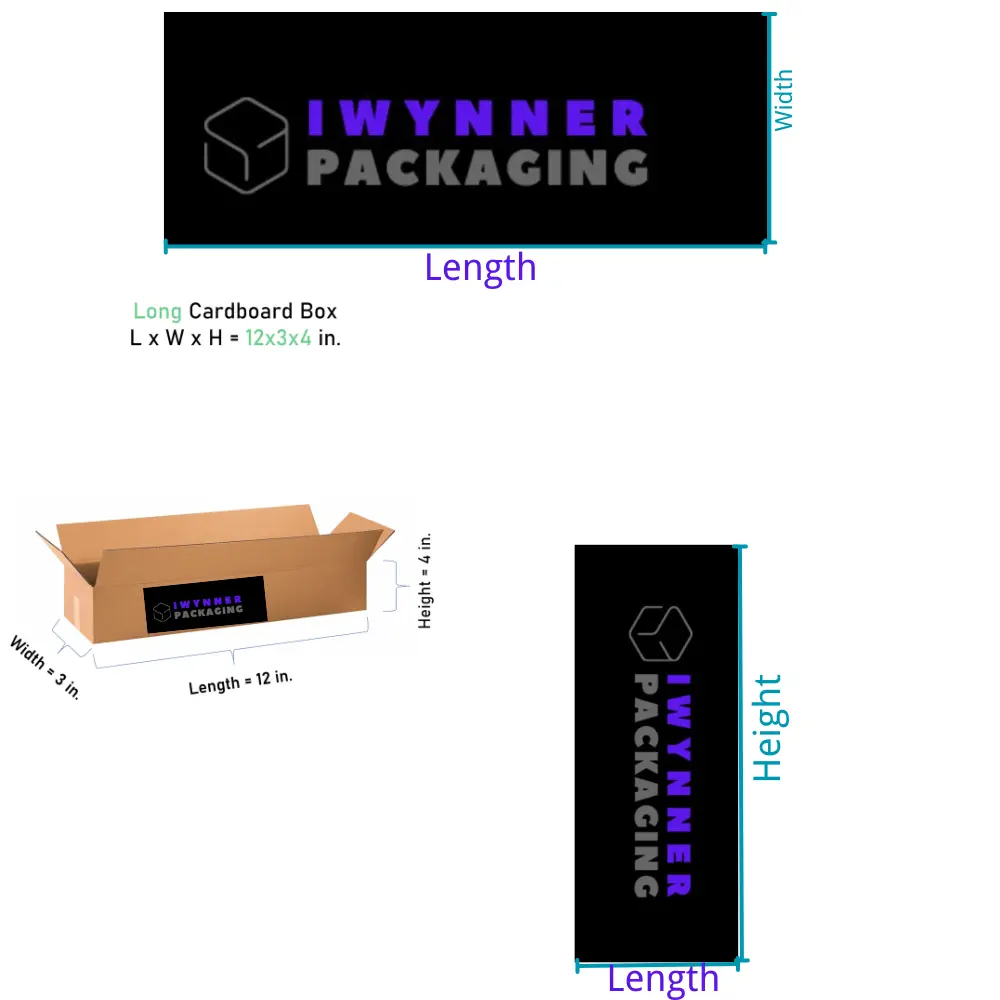

We all often hear how to customize packaging, but few of us know how to measure a box. Box dimensions include length, width, height, and depth, which technically means something different for everyone.

Measuring a box correctly is the key to product packaging design. While learning how to measure a box may sound a bit simple, there is more to it than you might think. In this article, we’ll dive into how to measure a box, both inside and outside, and how to properly record those measurements so you can accurately communicate them to your product packaging company. In addition, we’ll explore how to measure the volume of a box and why all of this is important when creating the ideal packaging for your product. To ensure we know exactly which side of the packaging these terms refer to, we’ve created these sizing guides for easy reference and communication.

How to measure boxes?

To measure a box, you will need to use a ruler or tape measure to measure the length, width, and height of the box. The dimensions listed are always the internal dimensions.

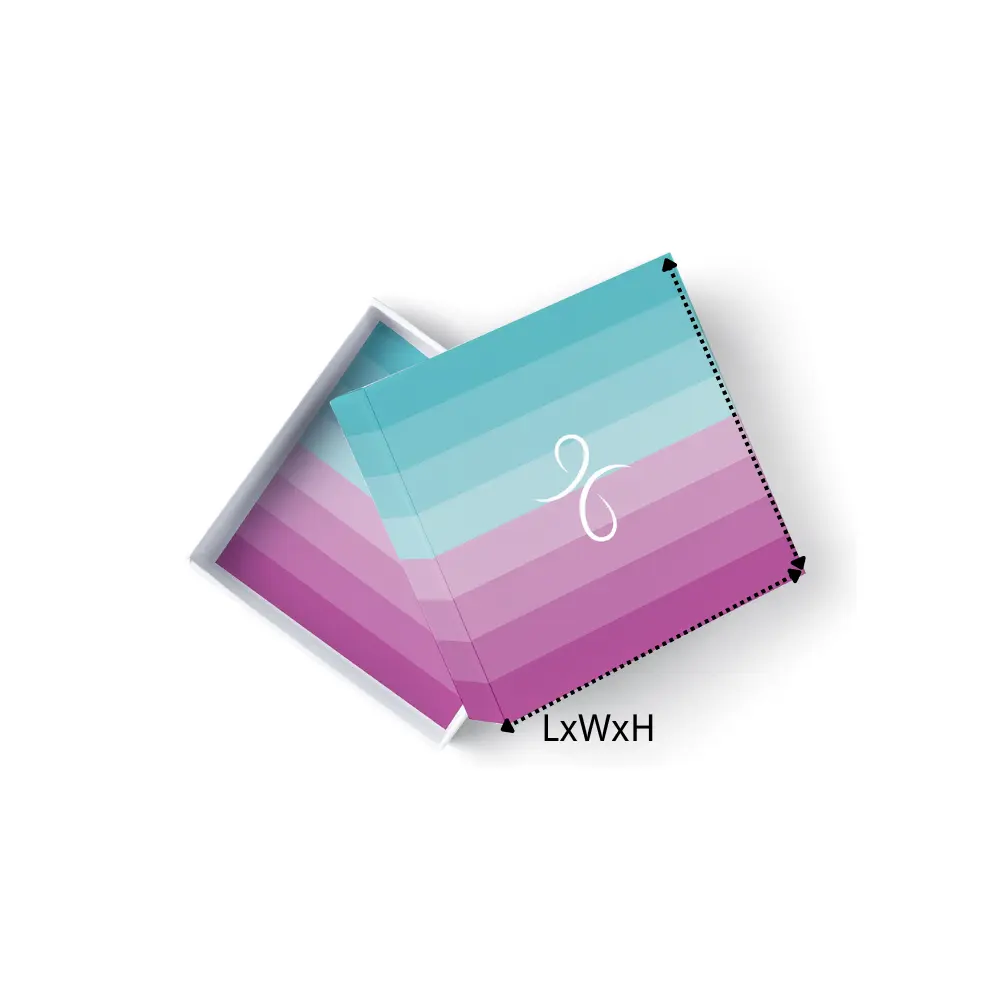

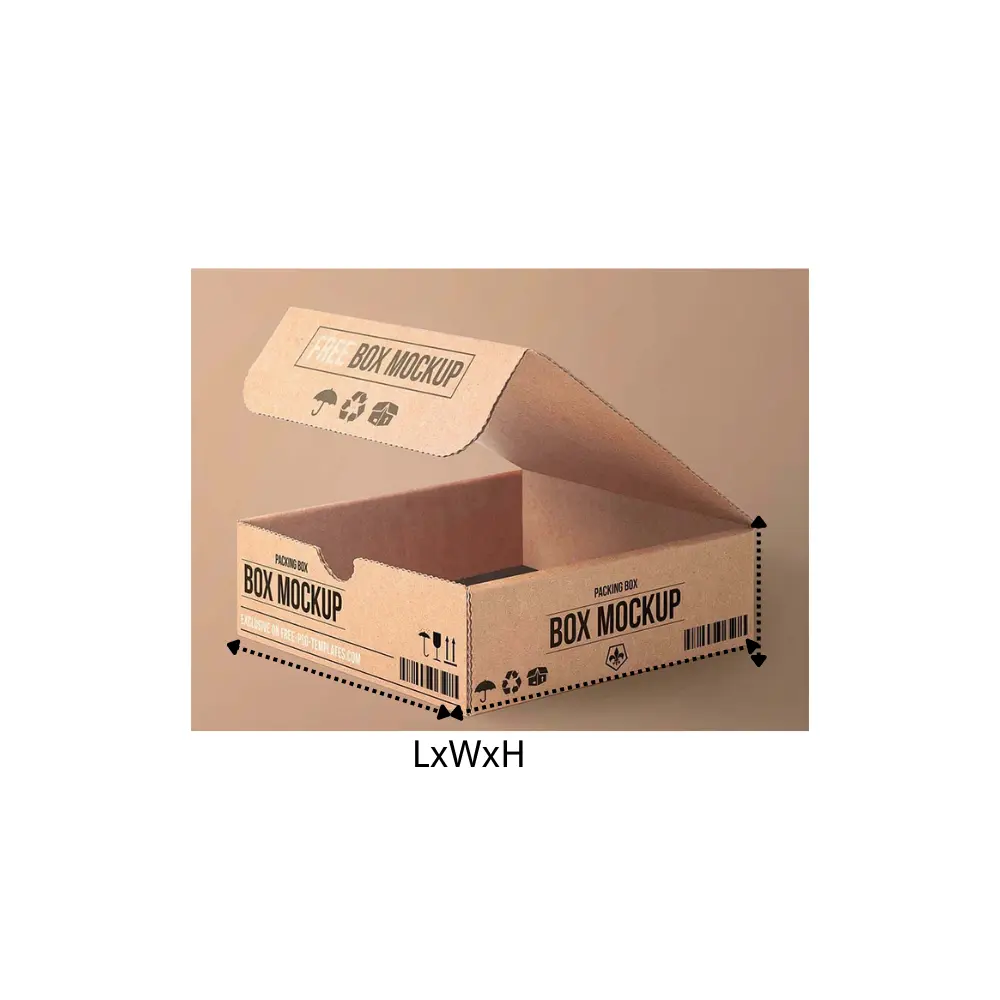

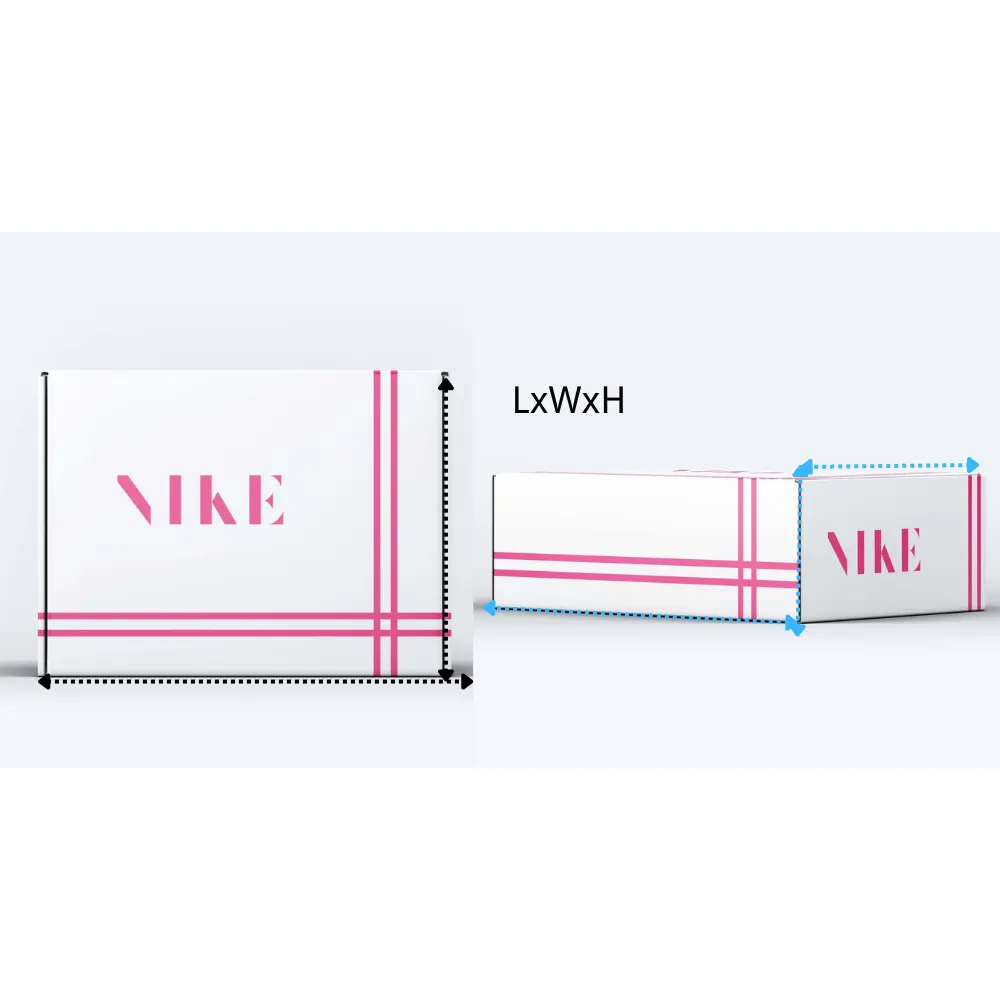

What does LxWxH mean?

To determine the dimensions of a box for custom packaging, you typically start by measuring its length, width, and height. This simple guide helps you better understand the size and shape of the box.

When it comes to measuring the dimensions of an object, we often use the notation L x W x H, which stands for Length, Width, and Height. The length-width measurements refer to the flat area of a product or box, while the height represents the vertical measurement. In the case of measuring a box’s dimensions (L x W), we label the larger of the two dimensions as length, while the shorter dimension is referred to as width.

To determine the dimensions of a box, first look at the open lid and determine the height of the box. The remaining dimensions are the length and width. The length is usually the larger dimension, while the last horizontal dimension is the width.

Sometimes, instead of using “H” for height, you may use “D” for depth. This is just a personal choice of the seller to better describe the shape of the product. In reality, height and depth refer to the same vertical dimension.

When viewing a box from the top, it is more intuitive to think of the downward measurement as depth. However, when looking at the same box from the front, the vertical dimension is seen as the height as viewed from the bottom. Different countries have different expressions, if you do not understand, please contact our packaging experts.

Three dimensions should to measured

- The first dimension of the measurement is the length. The length is always the longest side of a box with a flip-top lid.

- Next, turn the box 90 degrees and measure under the width, which also has a flap on the width side, but always on the side shorter than the length.

- Finally, measure the height of the package. The height is the only dimension without flaps. Measure the elevation of the box from top to bottom. The height measurement does not include flaps.

Note: Acceptable manufacturing deviation is +/- 1/8″.

What is the difference between 2D and 3d custom packaging?

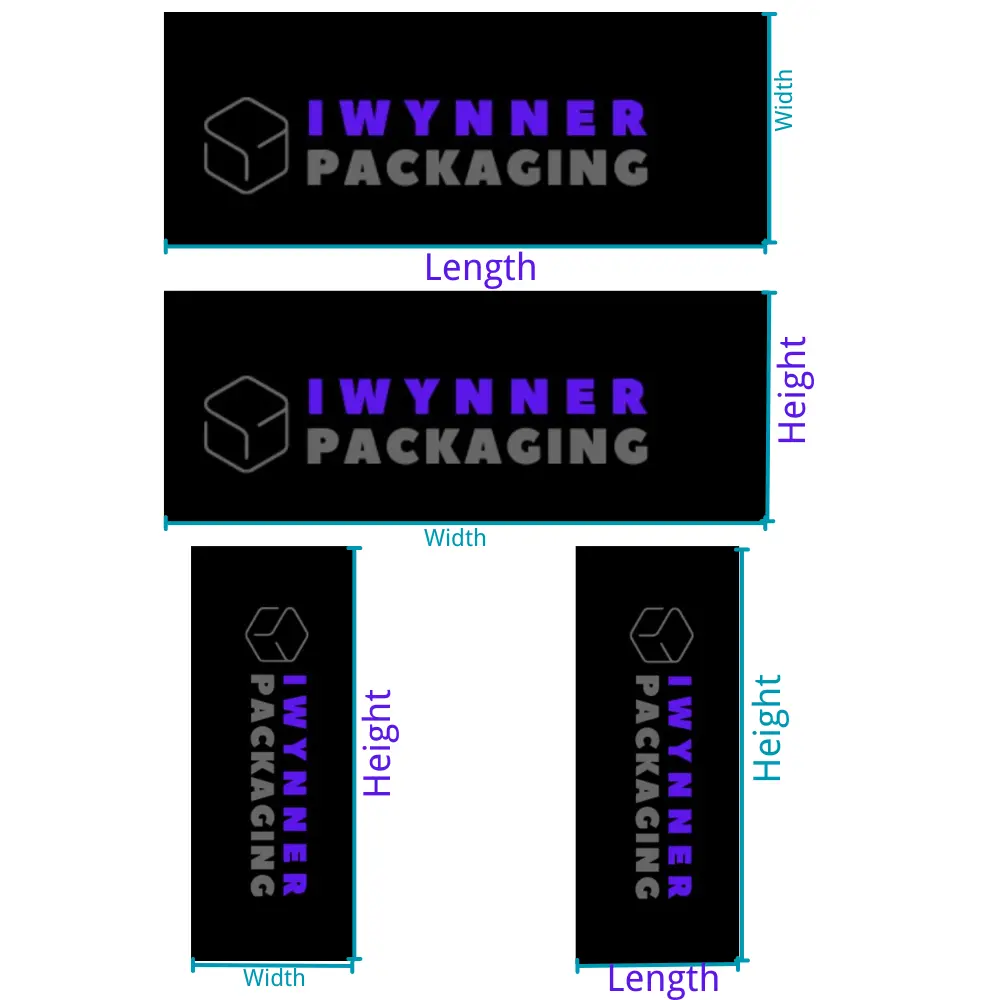

In the context of flat 2D packaging designs, there are typically two dimensions to consider: width and height. The term “length” is less commonly used in professional environments when referring to flat designs. However, it is worth noting that laypeople often use “length x width” instead of “width x height.”

Design and Illustration:

- 2D box packaging offers ample space to showcase brand logos, product names, and other messaging. Through large, two-dimensional surfaces, it effectively captures attention and reinforces brand identity.

Graphics and Art:

- By integrating graphics, illustrations, and other 2D elements, box packaging becomes visually captivating and appealing. These artistic elements enhance the overall aesthetic and contribute to a compelling packaging solution.

Labels and Information:

- 2D box packaging allows for the inclusion of labels, informative details, and other 2D elements. These components serve the purpose of conveying crucial information about the product, its usage instructions, and other relevant details to the consumers.

In the field of design and illustration, the standard order for dimensions is WxH (width x height) for both design and print work. This order is derived from mathematical matrix dimensions and is also commonly used in digital screen resolutions. Designers often prefer using the metric system for their dimensions to avoid dealing with fractions.

For instance, a vertical A4 design would be represented as WxH 210 x 297 mm (8.27 x 11.69 inches). However, if the orientation is changed to horizontal, the dimensions of the design box are inverted to 297 x 210 mm, but the WxH order is still maintained.

Example 2: Dimensions in Laymen’s Terms

On occasion, manufacturers and printers may use terms such as LxW (length-width) or LxH (length-height) to describe their products. In this context, the term “length” always refers to the horizontal dimensions relative to the branding and lettering on the packaging.

The WxH (width x height) order is commonly used in the design industry to minimize confusion among buyers who may not be familiar with industry standards. This method is generally preferred as it is considered the easiest for people to understand. However, it can create a conflict with the established industry standards that typically use the LxW (length-width) or LxH (length-height) order.

3D Packaging

When it comes to measuring a box for 3D packaging, it is customary to list the dimensions in the order of length-width-height. This standard packaging practice is followed by all professional box packaging designers and printers. By adhering to this order, it helps to avoid any confusion and ensures consistency across the industry.

Start measuring the size of the box

Before you can start calculating the dimensions of your box, you first need to know the dimensions of your product. There is no magic formula here, but using the same formula for measuring your product as you use to calculate box dimensions will keep you and your product packaging supplier on the same page, so it’s best to use the standard LxWxH formula to measure your product. (We will cover this measurement formula in depth later.) In general, the box your product comes in should be slightly larger than the product itself. Keeping a minimum amount of wiggle room will help prevent your product from moving around inside and getting broken.

How do I measure the outside or inside dimensions of a box?

A common mistake when measuring the dimensions of a box is to take an external measurement. Measuring the dimensions of a box this way does not properly take into account the thickness of the box, especially if you are using a heavier material like corrugated cardboard. The double-walled structure of corrugated cardboard can add considerable additional volume. Therefore, using internal dimensions will ensure a perfect fit with your product, no matter how thick your product packaging walls are. Using the outside dimensions runs the risk of the box being too small, your product being squeezed tightly against the side of the container, or not fitting at all. This is why most companies that offer product packaging require that the box size be obtained from the inside rather than the outside.

Internal size or external size

When you purchase a box from another distributor, the shipping box is measured using the inside dimensions. This is done to let you know how your product fits. When you measure a box that is shipped with a carrier such as UPS or FedEx, you will measure the outside dimensions of the box. By using the outside dimensions, the carrier can calculate exactly how much space is needed for the package.

Dimensional weight and shipping your package

Most freight carriers charge by the volumetric weight of the box or the actual weight, whichever is greater. They do this to maximize their profits, which makes it critical that shippers have the right size box for your product so you don’t overspend on shipping.

How to calculate the volume weight

Calculate the volume of the box

Knowing how to properly calculate the volume of a box makes it easier to gauge how much space it will take up. This is useful when determining things like how many boxes can be stacked on a pallet, and how much space each unit will take up in a warehouse. The method used to calculate volume is simple. Just multiply all the dimensions of your boxes together. The formula for volume is the same as the formula for box dimensions: length x width x height. However, keep in mind that the final measurement will be the cube – in other words, square inches, centimeters, or whatever units you use to calculate the box dimensions.

- Calculate the cubic dimension by multiplying the length by the width by the height of the box.

- Take the cubic dimensions of the box and divide them by the carrier’s divisor. For FedEx and UPS, the retail volume weight divisor is 139, and both DHL and USPS use 166 as the size factor for packages smaller than 1,728 cubic inches (or 1 cubic foot). For more detailed information, see Carriers.

- For carriers, the cost depends on the size of the box and the destination to which the package is shipped. The carrier will charge you a shipping fee based on the destination based on the cubic size of the package. For proper shipping costs, the dimensional weight needs to be accurate and not rounded up at all.Examples.All box dimensions are written as L x W x H. For example, 14″ x 11″ x 4″ means 14″ (L) x 11″ (W) x 4″ (H)”.

Measuring a box may seem simple! But with custom packaging, these dimensions are critical to the safety of your product! Please let us know if your box size is an inner box size or an outer box size.

Box dimensions are a critical part of any package because the size of the box affects the materials required, production costs, and shipping and storage costs. For example, minimal space for movement in the box means minimal space for damage and reduces your overall costs. Accurately measuring boxes for custom packaging projects is actually more complicated than it may seem at first glance.

Here, we list the top considerations and step-by-step guidelines for measuring box sizes.

While theoretically square boxes should have equal sides, this is unlikely to be true in packaging.

So make sure you measure each dimension accurately to ensure your packaging meets your product standards!

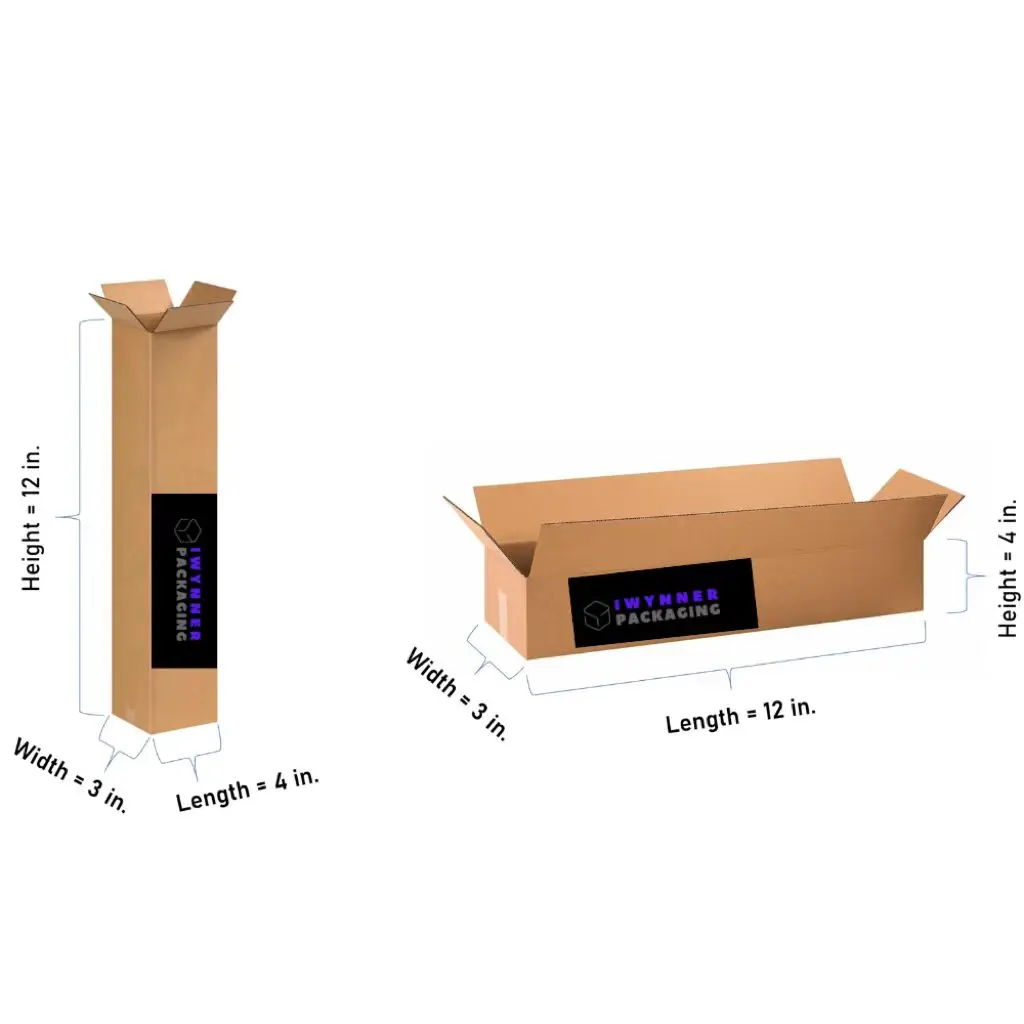

For long boxes, as shown below, the depth and width will be much smaller compared to the length.

The type of box you choose will depend on the shape and size of your product.

However, the size required for production, regardless of the type of box, will still depend on the length, width and depth.

The importance of internal dimensions

The industry standard for box dimensions is based on internal measurements.

The difference between internal and external dimensions is important to get a package that fits your product perfectly.

More accurate internal dimensions for both the manufacturer and your product!

Most manufacturers are very specific about the size of their internal and external dimensions, and rightly so.

After all, no one wants their product to be damaged because of incorrect measurements.

While it may seem more natural and easier to measure the outside dimensions of a box, it is the inside dimensions that are really important for your custom packaging project.

This ensures that your product will actually fit inside the box and that you can adjust the dimensions to ensure your product is secure.

Leaving minimal room for movement inside the box will keep your product safe during shipping and handling and allow your business to deliver a quality product every time.

The importance of external dimensions

If a box is measured by its external dimensions, it may prove problematic because the external dimensions do not take into account the thickness of the box, which can result in a less-than-adequate package.

This can damage a specific product that needs a tight-fitting package.

This is why calculating the size of a box by its internal dimensions can eliminate any concerns.

Corrugated boxes feature a fluted texture woven between two pieces of cardboard, thickening the material and adding a few millimeters to each measurement you take from the box’s outer liner.

That’s why internal dimensions will provide you with more accurate measurements, making it easier to determine the box size needed to package your product.

Why box measurements are important

Over the life of a product, boxes wear many hats. First, they act like a miniature billboard, enticing customers to pick up your product for a closer look (and hopefully put it in their physical or digital shopping cart!) . Without attractive product packaging, your merchandise is automatically at a disadvantage against competitors who have done their homework in creating product packaging.

The box is also the first – and sometimes the only – line of defense, protecting your product from damage during handling, storage and shipping. Your product will pass through many hands before it finally reaches your customer’s front door, mailbox or shopping bag. Therefore, the boxes that hold your products need to be designed to ensure that your goods are still in top condition when your customers receive them. If your products are designed to be stored in boxes after purchase, such as shoes or other more durable consumer goods, boxes also serve as a storage solution for the life of the product. With so many things depending on your box, it’s important to get your box dimensions right the first time.

Conclusion.

Boxes are a versatile tool in the product packaging world, making your products look great while protecting them from damage when they reach the consumer. Measuring the size of the boxes you need for your product range is only the first step. We work with a range of companies to create customizable folding cartons that look great and provide adequate protection during shipping.

If you have any questions about carton sizes, label selection or printing, don’t hesitate to contact our team by phone or live chat.