When designing packaging for your brand, you have a multitude of options to consider. For example, the board thickness is an important element to think about when choosing the proper packaging for your firm. So do you know anything about the paperboard thickness? This content will educate you about the paperboard.

What does GSM mean?

An abbreviation for grams per square meter. Its measurement refers to a material, regardless of whether its dimensions measure one meter by one meter or one square kilometer by one square kilometer.

What is GSM in paper weight?

GSM paper refers to the density of the paper. It refers to the weight of this paper. In other words: the higher GSM, the heavier the paper. Paper weight charts range from lightweight thin paper to heavier weight designs made from cardstock. GSM is the most common paper thickness unit used by the printing industry worldwide. Therefore, if you’re printing a carton that’s being sent door-to-door, you will need to know what studying unit that is so that you can determine the thickness of the packaging. If you are ordering customized thin paper or custom insert cards, this is the method the printer uses to differentiate between the different kinds of paper used in the manufacturing process. Thus, if you do not understand exactly what GSM is, you may make the wrong paper purchase as necessary. This is a costly mistake, especially if you are a small business! To ensure that your packaging has the right functionality, it pays to choose the right weight of the material.

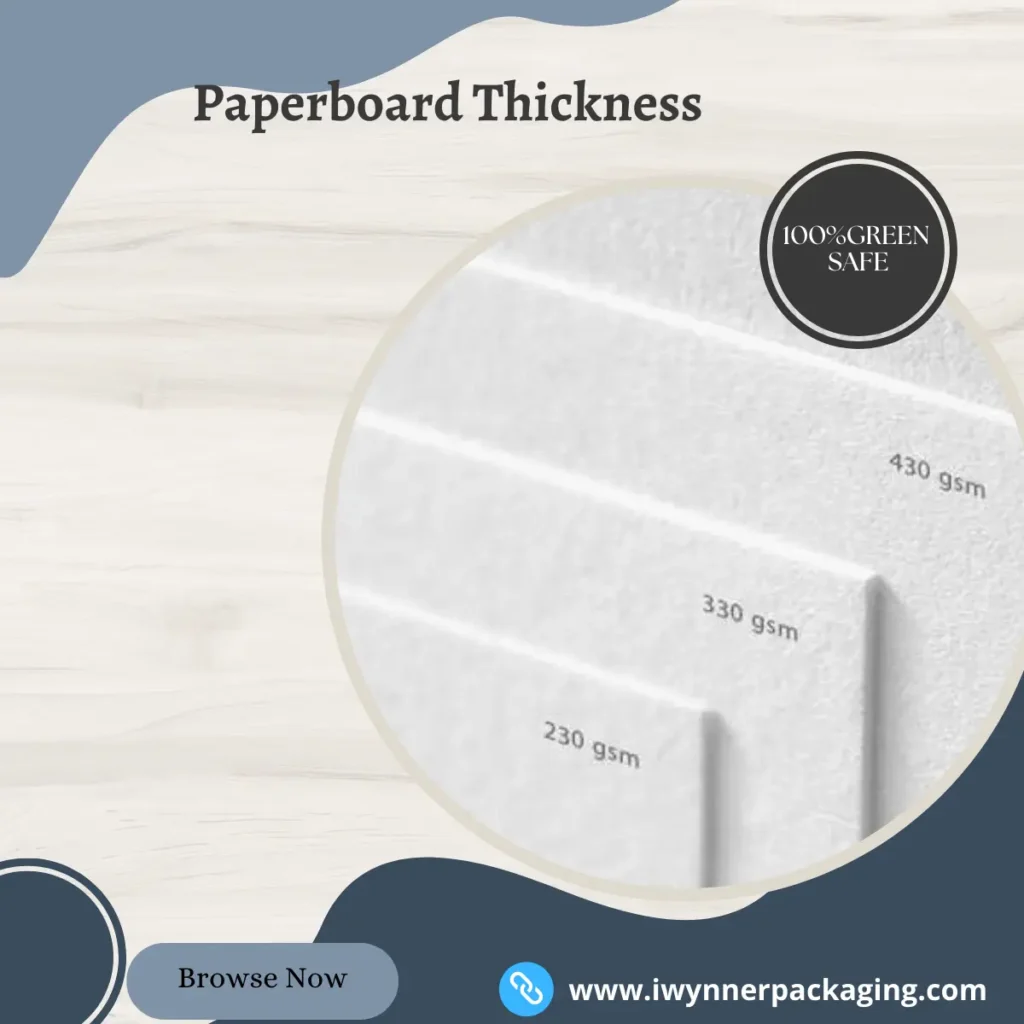

Understanding Paper Thickness

The paper weight chart below will give you a better idea of how to use different paper thicknesses. 35 – 55 GSM paper: The thinnest white paper available, primarily used for newspapers and magazines.

90 – 120 GSM paper: Regular copy or office paper weighs.

130 – 250 GSM paper: This is the most common (and economical) material used in promotional posters.

260 – 300 GSM paper: Heavy but bendable cards are suitable for high-end brochures and magazines with thickness.

350 – 450 GSM paper: The stiffest and heaviest paper weight which can hold plenty of weight and is thus used for business cards and invitations.

Understanding printed paper box material

For custom paper boxes, paper printed boxes are usually made of 4 kinds of paperboard. SBS paperboard is white inside and outside, widely used in cosmetic paper boxes. CUK, also known as SUS, is white outside and kraft brown inside, widely used in beer carriers, beer paper boxes, beverage paper boxes, etc. Kraft paperboard is kraft brown both inside and outside. It is used for making kraft paper boxes and corrugated printing boxes. CCNB cardboard is white outside and grays inside.

Why is the thickness of cardboard important?

It protects the content

It helps to survive in transportation

Minimizes shipping costs

Promotes optimal printing

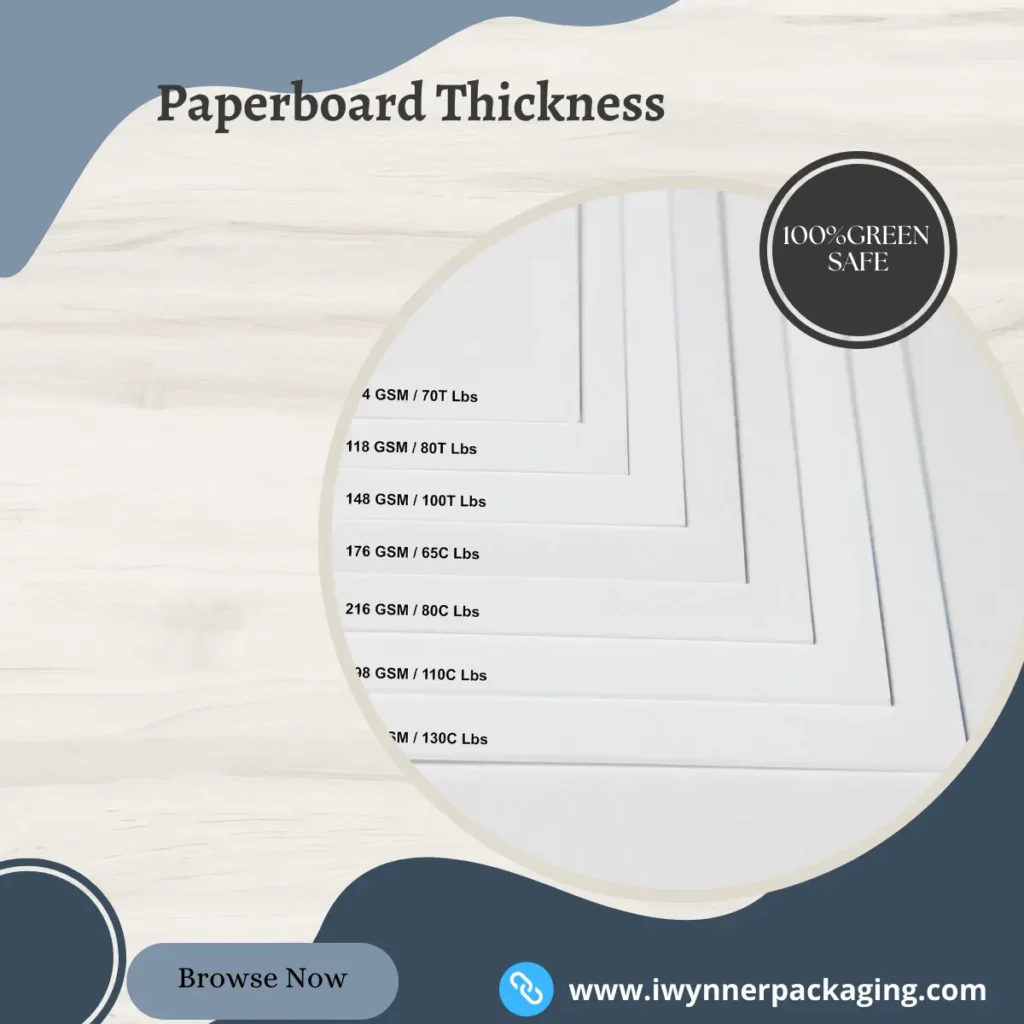

Paperboard thickness and grammage conversion table

Single copper, double copper, white cardboard, white kraft card, kraft card, grey background white board paper gsm, thickness and pt cross conversion table.

In China, the thickness of paperboard is measured in mm, whereas in America it is measured in p, abbreviated as Pt. ln(2) can be used to convert the two units.

1 inch = 25.4 mm = 1000 lbs. 1 pt = 0.0254mm

For example, 60 pt = 60 * 0.0254mm = 1.524mm. 60 pt particle board in the US refers to 1.5mm gray board in China, which is perfect for small rigid boxes. When you need a strong rigid box, you can use 80pt particle board, which is 2mm thick grey board in China.

How to choose the best packaging

Consider the following factors when choosing a package.

Contents

Shipping

Budget

Design

Now that you have a better understanding of the importance of cardboard thickness and how to measure it, how do you choose the best packaging for your product?

Who to work with to design your packaging?

Step 1: Consider the content

When choosing the best packaging for your brand, you first need to consider the content of the package. Is your product an extremely fragile item that needs extra protection? Is your product particularly heavy and requires very strong and durable packaging? These are two important components to keep in mind. In addition, That you choose packaging that is appropriate for the size of your product is vital. You want to choose boxes that are large enough to comfortably hold your products, but not so large that they will constantly move around. Packing additional custom inserts and dividers may be a good idea to help keep your products secure.

Step 2: Consider the shipping process

Think about the packaging options before you decide on the best packaging for your brand, and be sure to consider the shipping process as well. Do you have to package the order yourself, or are you using a local delivery service? If so, then you probably don’t need very durable packaging. But let’s say you use a third-party logistics to select, package, and ship your products. In this case, you must consider the possibility that the number of hands on the package will cause damage during shipping. Thus, you need to consider investing in sturdy, thick packaging to avoid damage and safeguard your products.

Step 3: Consider your budget

In addition to the cost of packaging goods, you should also contemplate the expense of shipping these packaging goods, as shipping expenses are determined by weight and size. Do not assume that thicker products necessarily weigh more.

You can consider cost when choosing packaging manufacturers, but you must also consider the shipping of these products, which is determined by size and weight. Just because something seems heavy does not mean it is thick.

The budget you select for your packaging company is likewise a significant factor in your packaging decisions. Not only must you have to think about the pricing of the packaging materials manufactured by the small business, but you also need to consider the delivery time and shipping price of these items to your company. please remember that thickness does not necessarily equal weight. Also, keep in mind that sometimes it is worth spending more money on thicker cardboard to provide more protection for your product.

Step 4: Consider the design

Consumers expect and respond to branded packaging with eye-catching designs that help create a memorable unboxing experience. Paperboard thickness is related to print quality, as it will print better on higher-quality paper with higher GSM. If you seek high-quality photographic prints on paper, select a sheet with a high number of GSMs.

Step 5: Work with a packaging specialist

Even if you know all about paperboard thickness, you might still wish to ask for assistance from a seasoned packaging specialist who will be able to help you choose the best packaging for your brand.

Choose the right paperboard for your needs.

1. Thicker materials aren’t always the best choice

One of the most widespread errors is to assume that thickness and grammage define the grade of the paperboard. Many companies choose the highest gram weight, fearing that the box will hold the weight of the product, or that it will be damaged during shipping. This is not always a good thing.

In fact, in addition to thickness and grammage, the choice must also be based on the toughness of the paperboard derived from the mechanical properties of the paper. For example, virgin fiber paper with the same thickness (such as Stora Enso Tambrite) has a higher strength than recycled paper since the virgin paper is made with wood pulp that can strengthen the structure.

By checking sturdiness, grammage, and thickness, the best paper can be chosen for the size and weight of any product. In fact, if the thickness of the paper is too high, some damage may occur during the manufacturing process of the package, such as low-quality folds, imperfect sealing and eventual manufacturing problems when filling the product.

2. Primary food packaging with virgin fiberboard

If you are planning food packaging, especially primary packaging, then the choice of material is crucial for direct contact food packaging. A version made from virgin pulp is among the right selections, as it is sourced from the operation and regrowth of spruce and birch trees certified for sale in the PEFC program (The program promotes responsible forest management and is administered by the Forest Stewardship Council).

Some additives (and sometimes mineral oil) may be found in the production of paper and recycled paperboard. If these substances come in contact with food, they may pose a risk to the health of consumers. However, Italian law allows the use of recycled paper for food purposes, setting a fairly high tolerance level for potentially harmful substances. This drastic regulation gap leaves plenty of room for discussions on very important topics in the field and, therefore, This will reduce the limitations of the laws in this respect.

This is why we recommend careful selection of virgin fiber or recycled paperboard in the production of food packaging.

3. Choose the right paperboard to use according to the design

As stated on several occasions, the packaging design should impress your customers and show part of the box contents. Choosing a paper that also delivers superior outcomes is an essential thing to do when choosing a professional for creating packaging. One of our most frequently asked questions regards which kind of paper is best for use in making cosmetic boxes. If you need a material with a higher white point, we recommend using virgin fiber paper such as Iggesund Invercote Creato, which is one of the most popular materials on the market. If you need to design an irregular box with lots of creases, it’s essential to use slightly less thick paper to avoid cardboard boxes tearing. In fact, the thickest paper is more likely to peel.

Conclusion

Paperboard thickness is an important factor in determining the toughness of your packaging, so if you don’t know how to choose, contact our team before placing your order.