Paper tubes are cylindrical packages used to hold a variety of different products, such as food and beverages. They come in many different sizes and can be printed or unprinted depending on your company’s needs.

Several materials and characteristics are commonly used for paper cans.

Greaseproof paper

Greaseproof paper is made of fine plant fiber by interweaving, in a wet state after free pulp, no sizing, no filler, paper copying, 72% concentrated sulfuric acid soaking 2 to 3s, washing with water and then treated with glycerin, dried to form a hard texture film type of material. Sulfuric acid paper is solid, dense and slightly transparent, with strong resistance to the penetration of grease and water, impermeable, and wet strength, etc. It can be waterproof, moisture-proof, oil-proof, sterilization and disinfection.

White kraft paper.

The biggest use of white kraft paper is used to package some food and medicine, because it is environmentally friendly, recyclable and biodegradable, and can be reused.

Kraft paper.

Smooth and neat. The paper of kraft paper is smooth and clean, kraft paper has good thermal compression elasticity, high flatness and stable heat transfer. The heat transfer performance of kraft paper is smooth, uniform and without fluctuations, and the heat transfer rate is moderate.

Black cardboard.

Black card paper is characterized by fine paper quality, translucent black, firm and thick, good folding resistance, flat and smooth surface, good stiffness, good tensile strength and high breakage resistance. The commonly used thickness of 120 grams – 350 grams of black cardboard. Because black cardboard is black inside and out, it cannot be printed with colorful patterns and is only suitable for hot stamping, silver stamping and other processes.

Writting paper.

White and smooth, poor resistance to breakage, generally used for cans only the whiteness of writing paper, in fact, is a very unsuitable material for making paper cans, but cost-effective, for the pursuit of price customers, you can choose to use a combination of writing paper and yarn tube paper

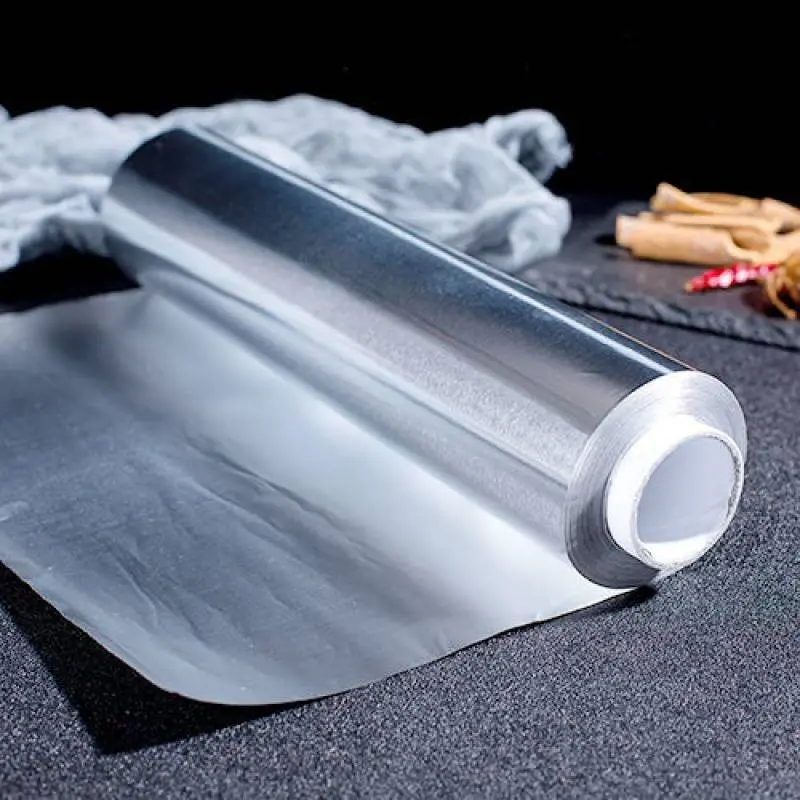

Aluminum foil paper.

Aluminum foil paper is a paper made of aluminum foil liner paper bonded with aluminum foil lamination. The quality is soft and easy to change shape, like paper, and it does not rebound after deformation. It can be qualitative, ensure shading, will not fall off, no light transmission, no pollution, for high-grade cigarettes, tea, candy and other food moisture-proof and decorative packaging.

Laminated paper.

Laminated paper, also known as white plastic paper, is composed of two layers, with a base paper and a laminated layer. The role of laminated paper is mainly moisture-proof, oil-proof, and play a role in the isolation of products.

The main feature is that this composite material can be oil-proof, waterproof (relatively), and can be heat-laminated. But it cannot be degraded.

Yarn tube paper.

A kind of industrial paper specially for the textile industry for making paper yarn tubes and conical paper tubes. It is a thin steel paper.

Yarn tube paper is mainly used in industrial tubes, film tubes, artillery tubes, textile tubes, spiral tubes, pagoda tubes, various paper corners, cartons, honeycomb cardboard, etc.

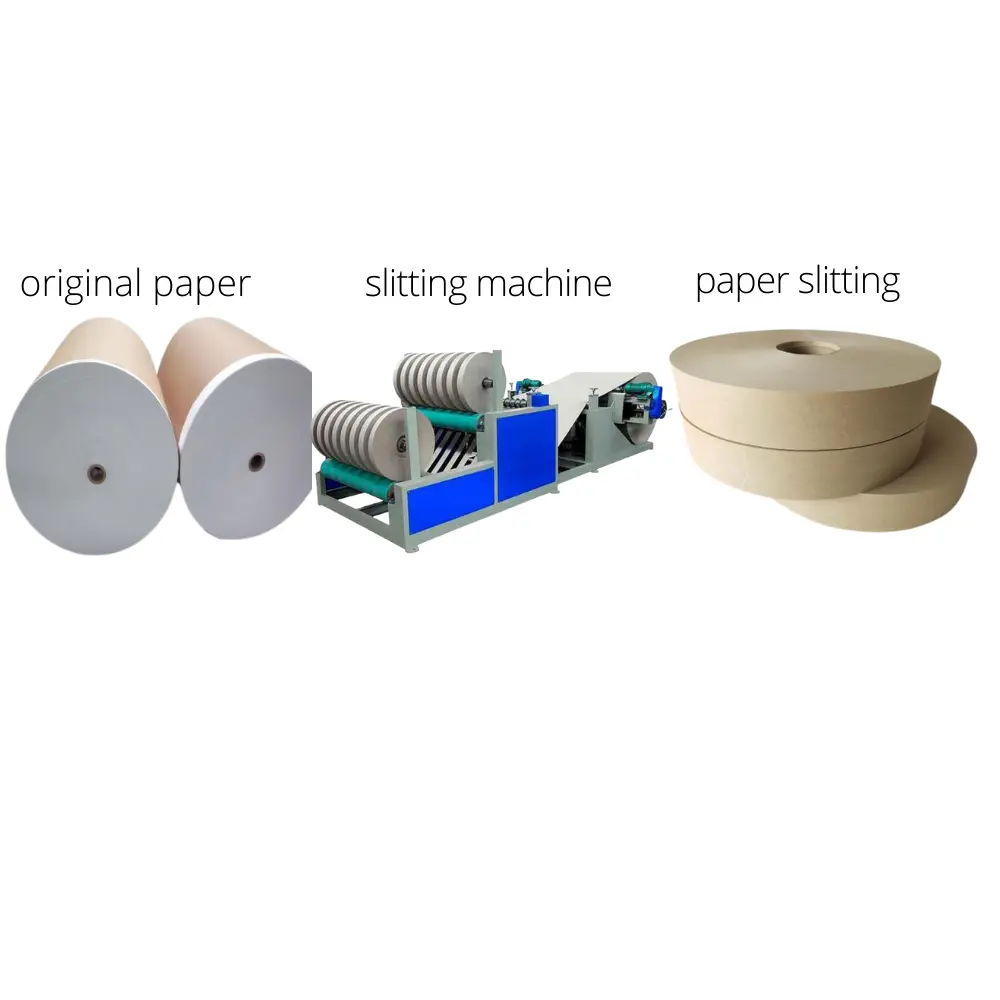

Original paper slitting-slitting machine.

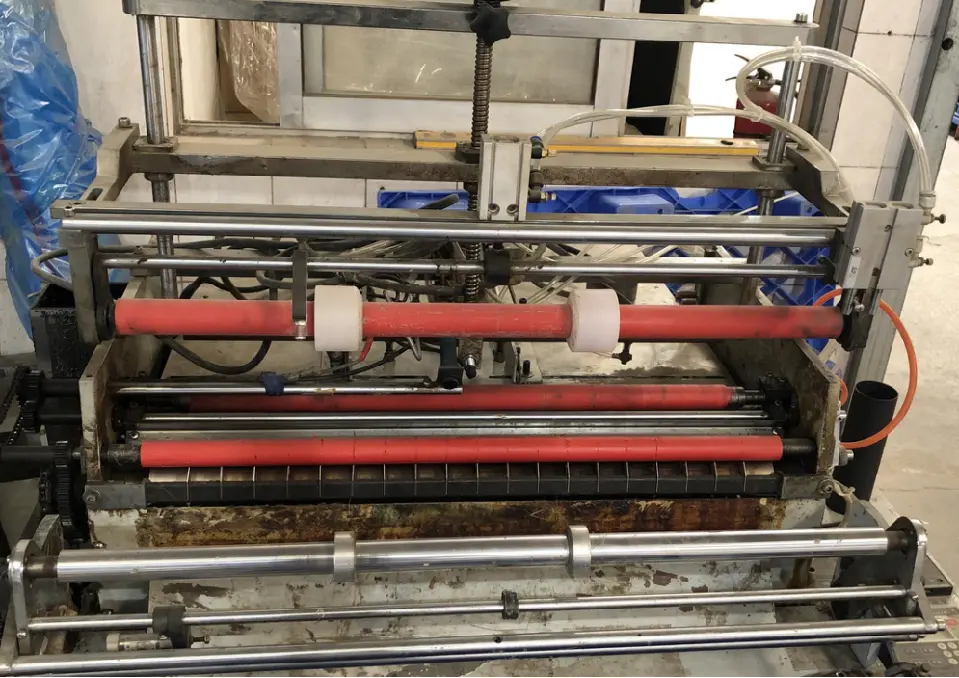

Tube-rolling machine-tube-rolling mold-tube-rolling glue

Pipe rolling demonstration

Spiral tube rolling machine working principle

Gear-belt-paper-rolling tube mold=rotary motion

Paper tube thickness-looseness-paper grams

First, the wall thickness of the paper tube according to the grams of paper to match, 600g of paper about 1mm thick.

Second, usually do the thickness of the can, we inside the tube 600g, outside the tube 600g to match.

Third, the grams of paper directly affect the paper cans opening and closing the tightness.

Fourth, different materials with the paper, some customers require black card, cow card and other differences with.

Fifth, the water content of the paper tube will also affect the elasticity, so to dry the tube.

Labeling-slitting-trimming-assembly

Labeling currently mainstream labeling there are two processes

Water glue labeling

Hot melt labeling

Water glue machine and hot melt machine labeling differences

1, water labeling machine high and low-temperature test results than the hot melt machine test results are much better, disadvantages: low yield, the surface glue stains, the need for many hands to clean up. Advantages: accurate alignment, the need for line alignment must be water glue machine labeling.

2, hot melt machine labeling machine, advantages: easy to operate, high yield, disadvantages: 2-3mm error on the line alignment. High and low-temperature test high temperature 85 °, low temperature -30 °.

Moisture control – tunnel oven

Water glue machine labeling must be controlled again after the water content of the paper cylinder, a good product must have links to control.

The hot melt adhesive labeling machine does not need to control the water content of the paper tube again.

Fine cutting, edge rolling, flattening, punching, bagging, full inspection, boxing

The common structure of paper cans

Heaven and earth cover structure, consisting of two paper cans, one large and one small.

Three-piece flat-edge paper tube, consisting of a lid, inner tube, and bottom.

Three-piece set of rolled-edge paper cans, consisting of a lid, inner tube, bottom

Tinplate composite paper cans, made of tinplate, paper tube composite

Plastic lid composite paper tubes, made of plastic lid and paper tube composite

Open window paper cans

Shaped rolled-edge paper cans, self-developed and Oval rolled-edge paper cans, runway-type rolled-edge paper cans, quadrilateral rolled-edge paper tubes.

Conclusion

Custom packaging is the way to go, we are a professional packaging supplier specializing in packaging for over 10 years, whether you are looking for custom boxes, our team of experts can help you find the perfect product for your company If you would like to learn more about how we can improve your sales by considering what people think when they see different types of packaging designs, please contact us today.