In many industries, embossers are used to validate documents with seals. From portable pocket models to sturdy desktop models, they come in a variety of shapes and sizes. It is easy to use and leaves a beautiful stamp with most embossers due to the simple embossing technique they use.

Let’s see how amazing embossing is in the packaging industry since embossing is very common there.

The origin of embossing?

Embossing dates back roughly to the 15th century when high-end stationery was made using heated pressboard. During the 19th century, embossing services became more affordable and convenient. Coins were mainly embossed using embossing techniques. Embossing possibilities have only grown over time. Documents and stationery were printed on them. Embossed effects can be achieved on paper in a variety of ways today.

How to emboss?

Embossing techniques include dry embossing, heat embossing, and embossing paper. The result is a minimalist yet professional raised image that blends seamlessly into the material.

An embossing machine commonly used for dry embossing uses a variation of this technique. Two stencils are used in the device, one with an embossed image and one with a recessed image. When the stencils are pressed together, they form a raised image. Foil stamping or paper embossing can be done with this embossers.

What industries can it be used in?

The use of embossing machines is widespread both in the professional and personal spheres. They can vary in size and shape based on their intended use.

Embossing process

An embossing die consists of two metal plates (front and back, also known as counter-dies) sandwiching the paper between them. By manually processing, engraving or lithographing the image to be embossed onto the two metal plates, the printer creates the die.

In the next step, the printer places the raw material between the front and back of the mold. As a secondary die, the male die will be at the bottom of the stock when embossing an image. When embossing, the male die will be on top, and the female die will be on the reverse.

Heat and pressure are used to press the die into the paper, producing a relief image. In blind embossing, the image is raised or depressed from the paper without using any ink or foil.

Nevertheless, you can add color to your molds or combine special print effects! Combining embossing with ink or foil can change the appearance of the embossed image. To create eye-catching or luxurious custom effects, glitter foil is often added to embossed logos or names.

What is embossing?

Embossed surfaces are the opposite of embossed surfaces. Embossing creates a recessed effect by imprinting your print with an image (logo, text, etc.). Similarly, ink or foil can be used to fill the recess.

You can use both sides of the print with embossing, unlike embossing, which interferes with the back. You can use it alone or in combination with embossing.

Notes on embossing and embossing

Investing a little more time upfront to get your project right will save you money and time in the long run. Before embossing elements of your print design, you must consider this first.

Vector art is a good place to start. Make sure your designer submits the final design as a vector art file, not a raster image. In vector art, mathematical rules allow resizing without compromising quality, so even the smoothest files can be embossed.

Choose the ideal part of your design for embossing. It is best to emboss text, logos, individual images, initials, and small patterns or embellishments. While embossing and intaglio can be used as a whole or as accents, there is no set rule that must be followed. Occasionally, embossing repeated elements on the entire side of a small print, such as an invitation or business card, can add a touch of class.

Make your artwork simple. As embossing adds a textural dimension to 2D images, simple artwork looks best embossed. If your artwork is shaded, colored, or otherwise designed for a 3D look, it may appear distorted when embossed.

When embossing a multilayered design, the deepest area should be the largest. Paper may tear if you emboss too deeply on a small part of your design. You should save your deep embossing for larger portions of your artwork.

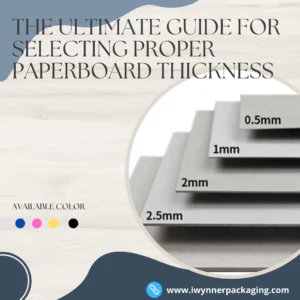

Use heavier paper if possible. To emphasize the depth and detail of an embossed graphic or image, fine dies and heavier paper are the most effective.

Embossing can affect the design on the back of the print. In this way, embossing does not limit you, but rather allows you to add some very cool visual effects.

Different techniques used for embossing

In order to determine which embossing technique is best for you, it is important to note the differences between the various techniques.

Dry embossing

Tracing the template on a piece of paper using a special stylus is one of the simplest techniques. As a result, the raised image is minimalist and professional.

Heat Embossing

The embossing process differs from “regular” embossing in that it is applied to designs that have already been pre-printed with embossing ink. A glossy, colorful pattern is embossed by adding embossing powder to the image and heating it.

Embossing Paste

Using a stencil, the user applies a special paste to the paper. An embossed image is created after the paste dries.

Other design tips

It is important to note, however, that die-cutting and embossing are not embossing techniques. Die-cutting cuts shape from material rather than creating a three-dimensional relief image. A die is a steel blade designed for die-cutting. Additionally, embossing can be used in conjunction with embossing. As opposed to a raised image, embossing creates a recessed image, which is inserted into the material.

Dry embossing is commonly used in embossing machines. Two stencils are used in the device, one with an embossed image and one with a recessed image. When you apply pressure to the stencils, they touch the material, leaving a raised image. Foil stamping or paper embossing can be done with these.

The color of hot foil stamping is black, gold foil, etc.

Advantages:

- Gives a metallic luster with strong contrast when printing pictures.

- It has a clear pattern, beautiful appearance, bright and eye-catching colors, and is resistant to wear and tear.

- The packaging design can be enhanced with foil stamped as an accent. It is suitable for text or logos that need to be highly visible. It is mostly used for cosmetic packaging boxes, essential oil bottles and tube boxes, eye shadow trays, lipstick tubes, etc.

Conclusion

The embossed design is not only an essential part of document verification and professionalism, but it is also a long-standing art form. All major industries will use embossing, regardless of the application.

Different types of paper are cheaper than doing additional embossing/embossing processes, you may consider using these finishes to decorate and enhance your packaging, It looks more classy. In the production process, kraft paper commonly uses UV coatings, embossing debossing on surface treatments to protect the layer.